Hardware Development

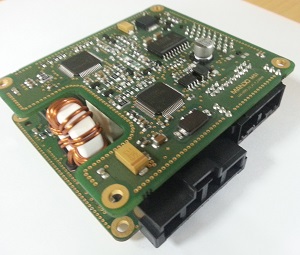

Automotive ECU

An Electronic Control Unit (ECU) is any embedded system in automotive electronics that controls one or more of the electrical systems or subsystems in a vehicle.

We are working on Automotive ECU which are mostly concerned with safety of vehicle and human life.

Brake , Steering , Suspension , ADAS , Electric vehicle ECUs are our major development areas.

We perform complete hardware development lifecycle which includes designing an ECU from a conceptual idea to mass production following ISO26262 functional safety process.

We have a complete team of expert engineers involved in concept design, circuit development, PCB development , Housing development , EMC & thermal analysis as well.

ECU Hardware Development

ECU HW development mainly focuses on Circuit development cycle. It starts from conceptualizing of hardware architecture to testing of DV samples to supporting in vehicle testing adhering to functional safety standards ISO26262.

Main Work Area

- Hardware Architecture

- Circuit design & BOM

- System level simulation

- Proto Sample development

- Hardware Unit & Integration test

- Create virtual car environment for ECU

- Automate test cases for ECU Validation

- Semiconductor Validation

- Engineering Test

- Fault Injection Test

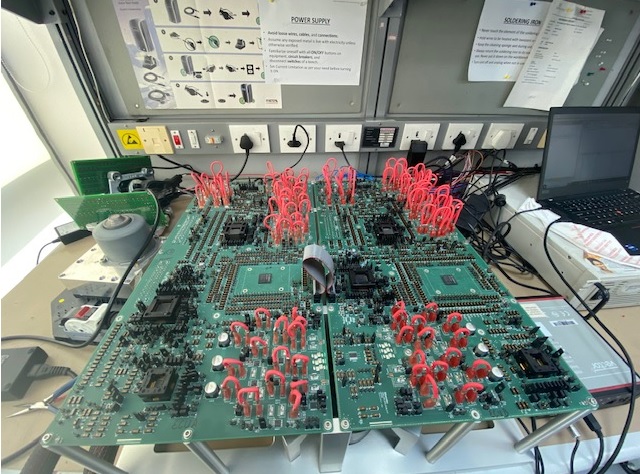

Fault Injection Test set up

- HARA – Analyze ASIL level

- FMEA - Analyze safety hazards-RPN

- FMEDA - Hardware architecture metrics

- FTA - Random Hardware Failures-PMHF

Main Project

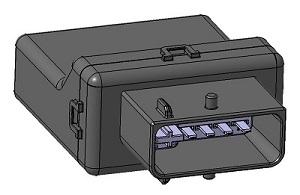

- Integrated Dynamic Brake

- Integrated Dynamic Brake with Redundancy

- Integrated Dynamic Brake with Parking Lock

- Integrated Dynamic Brake with Park by Brake

- Inverter ECU with 2.8kW, 9kW

- Hub Motor design and analysis

- Center Motor design and analysis

Inverter ECU

Upcoming Technology & Innovations

- Working with HL MDK on EV vehicle ECU design for Fully & Hybrid Electric vehicles

- System simulation of EV vehicle

- Enhance validation capability for high performance devices

- Secure semiconductor reliability technology

PCB Design

PCB Design

PCB Team co works with Global HL Mando subsidiaries (HL MDK, HL MSI, HL MRE) to make best in class PCBs. PCB is designed considering all Electrical (DFE, EMC/EMI, ESD), Mechanical (PCB 3D Model, Housing Interference), Thermal and Fabrication/Assembly (DFM, DFA) requirements.

Main Work Area

- Mass Product Design based on Automotive Environments

- Compliance to IPC and Automotive standards

- Global HL Mando PCB Specs

- PCB 3D step modeling

- Rigid-Flex, Ceramic, Embedded PCB Design

- Electronic parts creation and update

- Centralized Database Management

- Parts Mechanical and Electrical information

- DFM Verification

- DFE Verification

- CAM Verification

- PCB trace current carrying capacity calculation

- Assembly Data

- CAM Data

- Stencil Data

- ICT JIG Data

Main Products

- Brakes (MoCi, ESCi, IDB, EMB)

- Steering (CEPS, REPS)

- Suspension (SDC, SCU)

- ADAS (DCU, SPAS, PCU)

- Gate Diver, Logic Card

- Integrated Design (MoC+SDC, MOC+ABS)

- Low Cost Design ( MoCi Next Generation, RCU)

- Robot & Parking Platform (48V Robots)

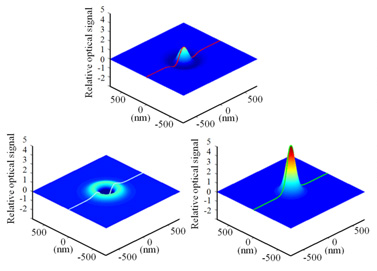

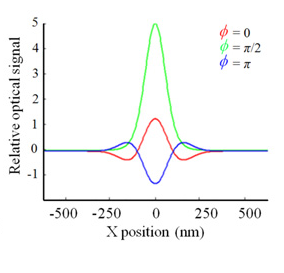

EMC Analysis

EMC Simulation

The increase in electronics activity has posed potential electromagnetic interference (EMI) hazards for sensitive electrical and electronics equipment used in many areas.

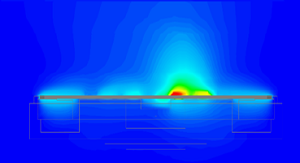

EMI/EMC analysis in the development process of the product / system in order to identify critical issues and fix them in the beginning. Our EMC team engineers bring strong knowledge in SI theory and expertise in simulation tools to Analyze various SI/PI issues like reflection due to impedance mismatch, crosstalk, signal attenuation and PDN noise, including conducted & radiated emission noise. The analysis is carried out in pre and post-layout analysis. EMI/EMC includes project execution experience of building concepts of EMI/EMC, EMI source, Automotive Standards (CISPR25), Control Techniques, Measurements and providing competent EMI/EMC design solutions, and optimization early in the development cycle.

Main Work Area

- Signal Integrity Analysis (SI Analysis)

- Power Integrity Analysis (PI Analysis)

- Conducted Emission Analysis

- Radiated Emission Analysis

- Parasitic RLGC Extraction

- Radiated Immunity/Susceptibility Analysis

Upcoming Technology & Innovation

- Conducted Immunity/Susceptibility Analysis

- Transient immunity & Transient emission

Thermal Analysis

Thermal Simulation

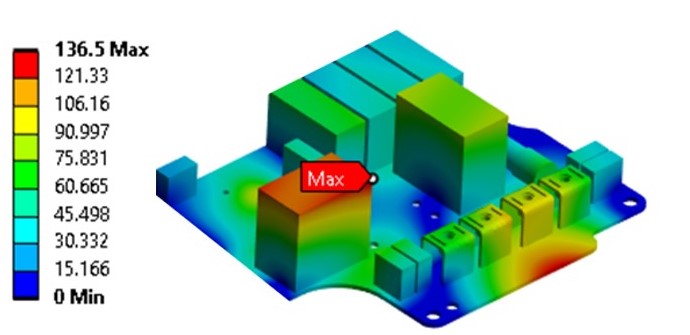

Thermal Analysis team is responsible for Thermal, CFD, Thermal Stress analysis of ECU and Motor design. Aim is to improve heat dissipation performance and reduce the risk of failure due to temperature rise.

Main Work Area

- Thermal analysis of ECUs at component level, PCB level and system level.

- CFD analysis to check fluid flow

- Thermal-stress simulation to check failure of the system due to stress generated by temperature

- Electro-thermal simulation

Upcoming Technology & Innovation

- Electro-thermal simulation

- Thermo-mechanical simulation

- Thermal simulation of battery management system

Housing Development

ECU Housing

Stress on pcb assembly

Housing design team is responsible for design of ECUs exterior case or enclosure used to protect an interior mechanism, including motor housing & its components. Aim is to optimize design to reduce weight and cost of the product as per the market trend.

Main Work Area

Housing Design

- 3D architecture of ECU housing and Motor parts such as rotor, stator, magnet, shaft, core, housing, terminal, etc

- Detailed drawings to describe each part structure for the manufacturing

- 2D drawings

- PCB mechanical interference check

- Selection of the material based on the application

- Design validation based on the manufacturing process and material

Upcoming Technology & Innovation

- Burst analysis due to pressure

- Topology optimization.

- Creep test for plastic assemblies

ECUs Structural Analysis

- Housing stress & Strain analysis

- Deformation analysis

- Vibration analysis

- Shock & drop test analysis

Achievements

Achievements

Participated in Halla Future day in 2019 & 2020- Black Box (2019) : Got 4th position award at Global HL Mando

- V2V Communication System : Appreciated by Global HL Mando Selection Team

- SDC Simulator

- MHI Simulator